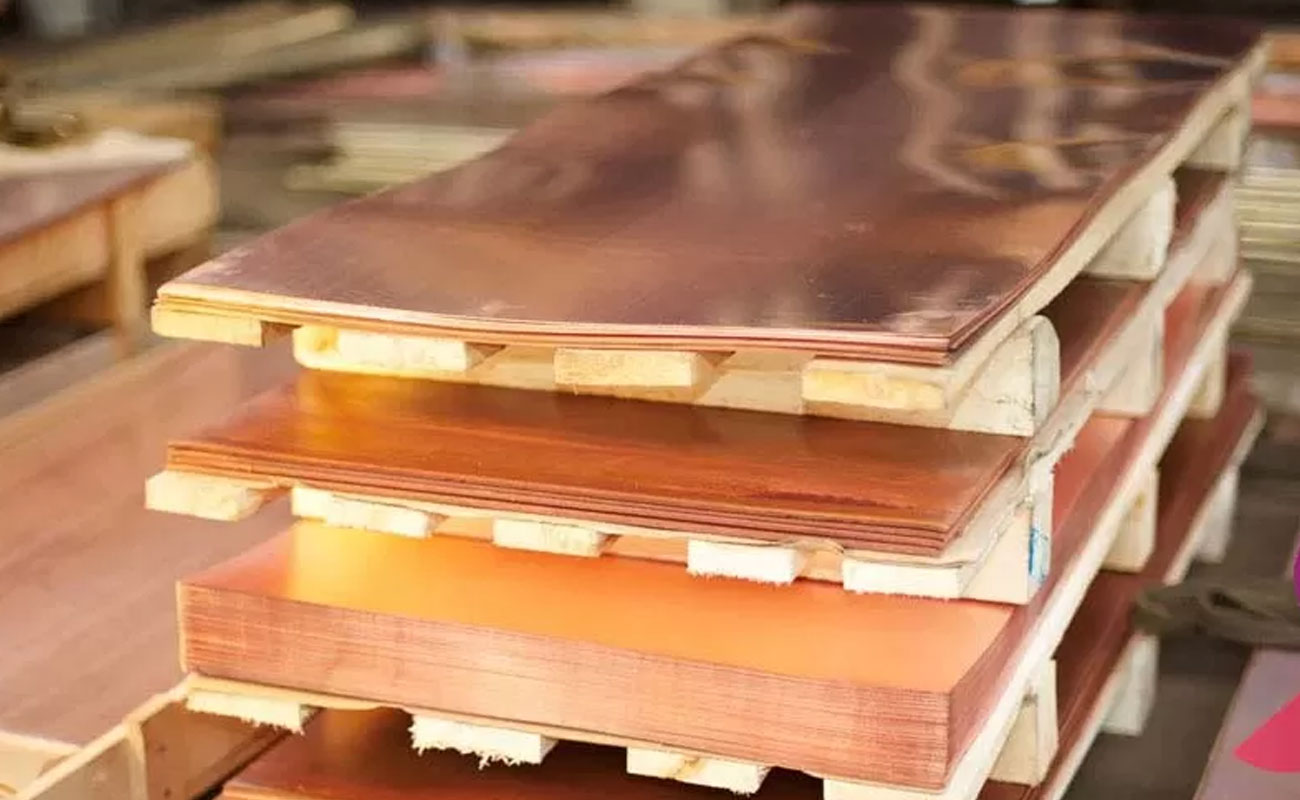

What is Copper Nickel Plate ?

Copper Nickel Polished Plate is a wrought commercially pure Copper Nickel with a maximum carbon level of 0.15%. This alloy provides highly ductile mechanical properties. Copper Nickel Plate is a solid solution strengthened, commercially pure wrought materials having excellent mechanical properties and resistance. Cu-Ni Sheet is extremely resistance to caustic alkalies. Bright annealed Copper Nickel sheet the metal finds applications in the handling of foods, synthetic fibers and caustic alkalies, and also in structural applications. CuNi Plate is commercially pure and has good mechanical properties and excellent corrosion resistance to alkalis. Cupro Nickel sheet is a 99.6% pure wrought Copper Nickel alloy. Sold under the brand names Copper Nickel Alloy Ni-200. Cupro Nickel Coil is commercially pure wrought Copper Nickel grade and has a number of useful characteristics including good ductility and mechanical properties. Cu-Ni Strip is 99.6% pure Copper Nickel, one of the toughest metals. Copper Nickel 200′s characteristics include excellent mechanical properties, magnetic properties, a low gas content, low vapor- pressure,high thermal and electrical conductivity.

Our widest stock of Copper Nickel Polished Plate enable us for prompt delivery to Middle east, Gulf countries, far east asian countries in any emergency, later in year 1990, we were recognised as a leading Distributor of Copper Nickel Plate in India, we can offer Cu-Ni Strip at dealer price which proves us that we are one of the best stockist of Cu-Ni Sheet in India.in year 1995, We became largest Stockist of Cupro Nickel sheet in India, currently we have ready stock of Cupro Nickel Coil at our stockyard in Mumbai, Maharashtra. We are the only Supplier in india who maintains Copper Nickel Plate in all Sizes.

Copper Nickel Plate Specification

| SHEET, PLATE & COIL | ||

|---|---|---|

| Sizes: Sheet & Plate.012 TO 4.00 X r/w X R/L

Sizes: Coil .001 to .011 x R/W x R/L |

GRADE | SPECIFICATIONS |

| 6AL-4V, 6AL-4V ELI | AMS-4911, 4907,4905, MIL-T-9046, ASTM-F136 | |

| DMS-1592, GM-3103,12TM-B265 | ||

| 6AL-2SN-4ZR-2MO | AMS,4919, MIL-T-9046, DMS-2275, AMS-T-9046 | |

| GM-3104, B50TF21 | ||

| 6AL-6V-2SN | AMS-4918, MIL-T-9046, DMS-1879, AMS-T-9046 | |

| 5AL-2.55N, 5-2.5 ELI | AMS-4909, 4910, MIL-T-9046, AMS-T-9046 | |

| BAL-IMO-1V | AMS-4915, 4916, DMS-1784 | |

| CP-GRADES 1,2,3,4 | AMS-4900, 4902 | |

| MIL-T-9046, AMS-T-9046, DMS-1536, ASTM-B265 | ||

| 15V-3CR-3SN-3AL | AMS-4914 | |

| Ni200 | UNS N02200 | ASTM B163/ ASME SB163 | ||

| Ni201 | UNS N02201 | ASTM B163/ ASME SB163 | ||

| Alloy 400 | UNS N04400 | ASTM B163/ ASME SB163 ASTM B730/ ASME SB730 | ||

| Alloy 401 | UNS N04401 | ASTM B163/ ASME SB163 ASTM B730/ ASME SB730 | ||

| Alloy 600 | UNS N06600 | ASTM B163/ ASME SB163 ASTM B751/ ASME SB751 | ||

| Alloy 601 | UNS N06601 | ASTM B163/ ASME SB163 ASTM B751/ ASME SB751 | ||

| Alloy 625 | UNS N06625 | ASTM B444/ ASME SB444 ASTM B751/ ASME SB751 | ||

| Alloy 718 | UNS N07718 | ASME CODE CASE N-253 AMS 5589 AMS 5590 | ||

| Alloy 800 | UNS N08800 | ASTM B407/ ASME SB407 ASTM B751/ ASME SB751 | ||

| Alloy 800H | UNS N08801 | ASTM B407/ ASME SB407 ASTM B751/ ASME SB751 | ||

| Alloy 800HT | UNS N08811 | ASTM B407/ ASME SB407 ASTM B751/ ASME SB751 | ||

| Alloy 825 | UNS N08825 | ASTM B163/ ASME SB163 ASTM B751/ ASME SB751 | ||

| Alloy 904L | UNS N08904 | ASTM B677/ ASME SB677 ASTM B673/ ASME SB673 | ||

| Alloy 20 | UNS N08020 | ASTM B729/ ASME SB729 ASTM B775/ ASME SB775 | ||

| C276 | UNS N10276 | ASTM B622/ ASME SB622 ASTM B626/ ASME SB 626 | ||

Why Choose Reliable Steel Distributors ?

- We are dominant Super Duplex Ferralium 255 Pipes & Tubes Manufacturers in India

- We are ISO 9001:2008 Certified Super Duplex Ferralium 255 Pipes & Tubes Suppliers in India

- We are Renowned Super Duplex Ferralium 255 Pipes & Tubes Exporters in India

- We are Supreme Super Duplex Ferralium 255 Pipes & Tubes Distributors in India

- Best Quality Super Duplex Ferralium 255 Pipes & Tubes Traders in India

- Largest Super Duplex Ferralium 255 Pipes & Tubes Stockist in India

- Best Price Super Duplex Ferralium 255 Pipes & Tubes Wholesaler in India

- Well Known Brand of Super Duplex Ferralium 255 Pipes & Tubes Importers in India

- We are 5th Largest Super Duplex Ferralium 255 Pipes & Tubes Stockholder in India

- We are Reputed Super Duplex Ferralium 255 Pipes & Tubes Manufacturer in Mumbai, Maharashtra

- We are Leading Super Duplex Ferralium 255 Pipes & Tubes Manufacturers in Rajkot, Gujarat